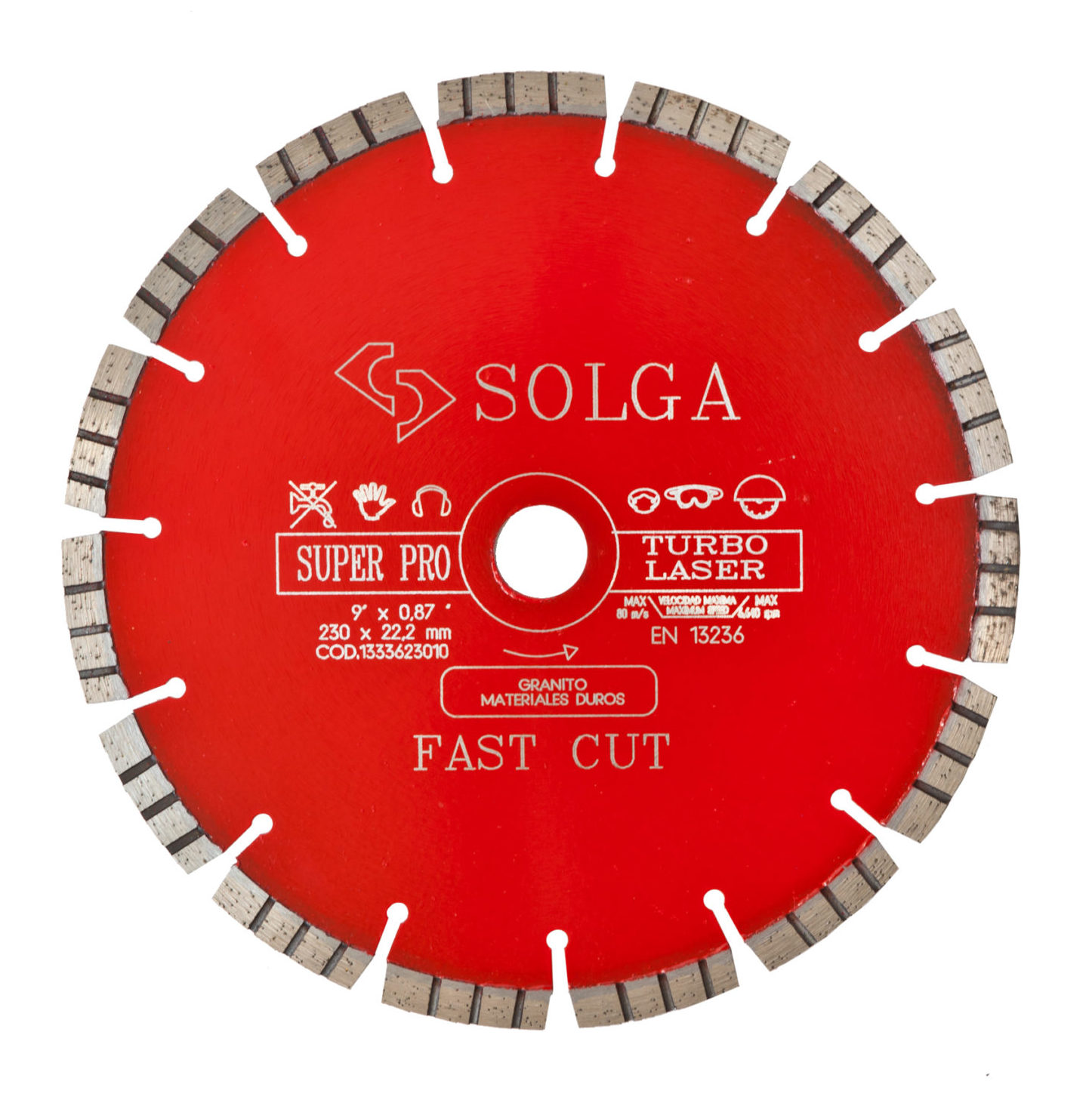

Disc Hard Materials (Granite) Turbo Laser – Dry Cutting Disc – Instagram

SOLGA DIAMANT, has a wide range of discs for dry cutting, from discs for low requirements or professional applications to very specific applications. All our segmented discs are welded by laser technology, always guaranteeing the safety of the operator.

Our technical sales team will support you in choosing the best option by analyzing the requirements of the job, type of machine and material to be cut.

SOLGA Diamant has a wide range of specifications, see thefollowing table with the codes we have.

Table Available Coming Soon…

At SOLGA Diamant, our goal is the highest quality by offering the best service. We select our raw material suppliers with the same premise that we use in our manufacturing, guaranteeing the highest level of quality. In our production process, we use the latest technologies in sintering and welding, obtaining products of the highest quality at competitive prices. Our commercial network collects the needs of the different markets, managing with the factory the development of new drill bits, continuously innovating to offer the best solution to each need. All our bits are welded by laser welding, induction welding is also available.

To check availability of a specific diameter you can contact us in the Contact link and also for technical questions about any of our products.