Polishing for natural stone

Please contact us to answer any questions you may have about our natural stone polishing products.

The introduction of diamond in the treatment of surfaces in the natural stone industry, has revolutionized the way of work allowing greater production of calibration and polishing lines, significantly improving the finishing of the plates. We develop alloys and internal processes to obtain our polishing tools, always seeking to obtain the best polishing process and performance.

Advantages

• For its lower working pressure, it reduces the power consumption of the head to 50%.

• This lower pressure allows you to work with fewer loads and results in significant savings in machine maintenance and repairs.

• Sludge production is lower so the evacuation of sludge is reduced while preserving the environment.

• The high duration of the diamond allows production to be maintained for a long period of time without stopping the line, with a total use of working time.

• High performance makes Frankurt segments a perfect choice when it comes to price-durability ratio.

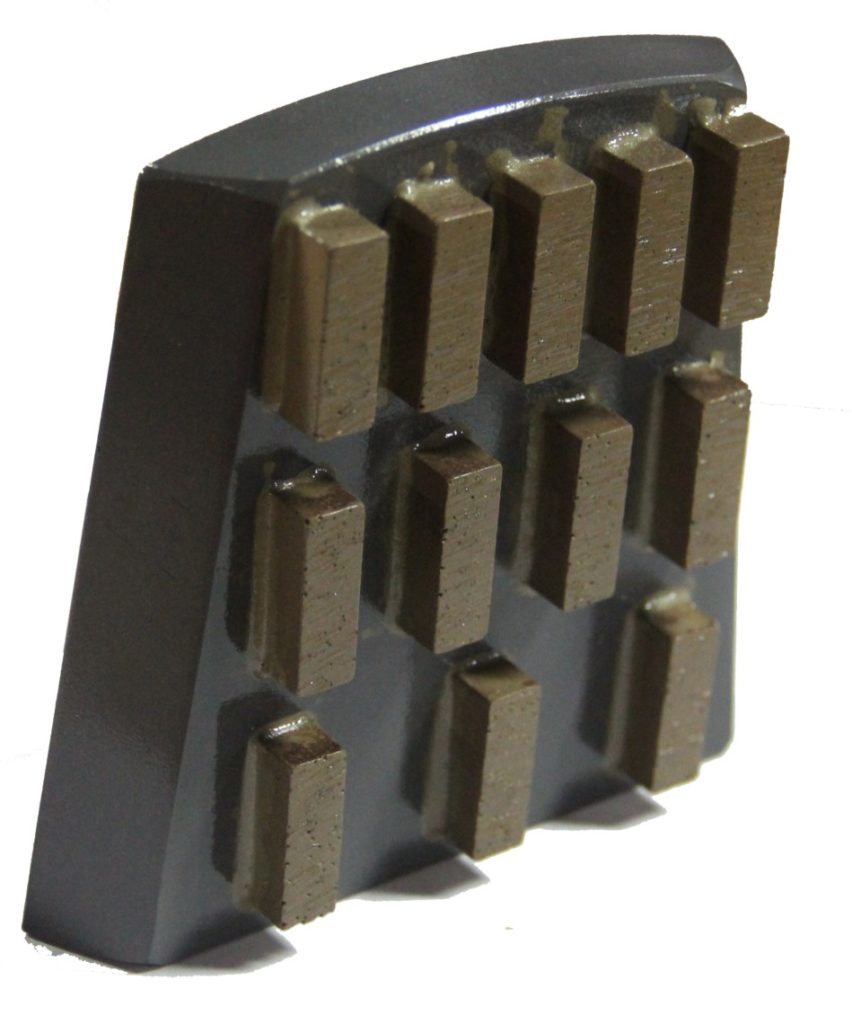

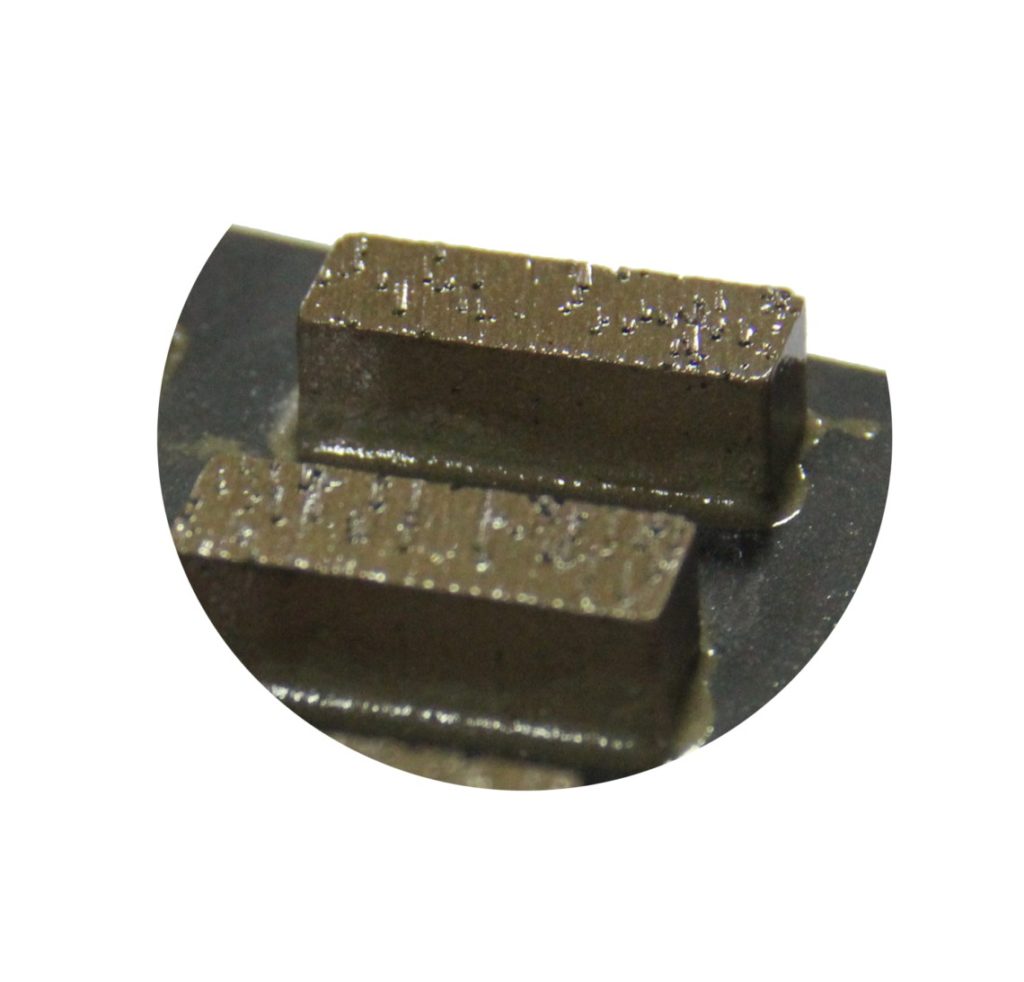

FRANKFURTS

Frankfurt type segments are designed for use in high production polishers for cementing and polishing marble.

They outperate the conventional abrasive with a lot of advantage and their results are very advantageous from all points of view. Available in various configurations.

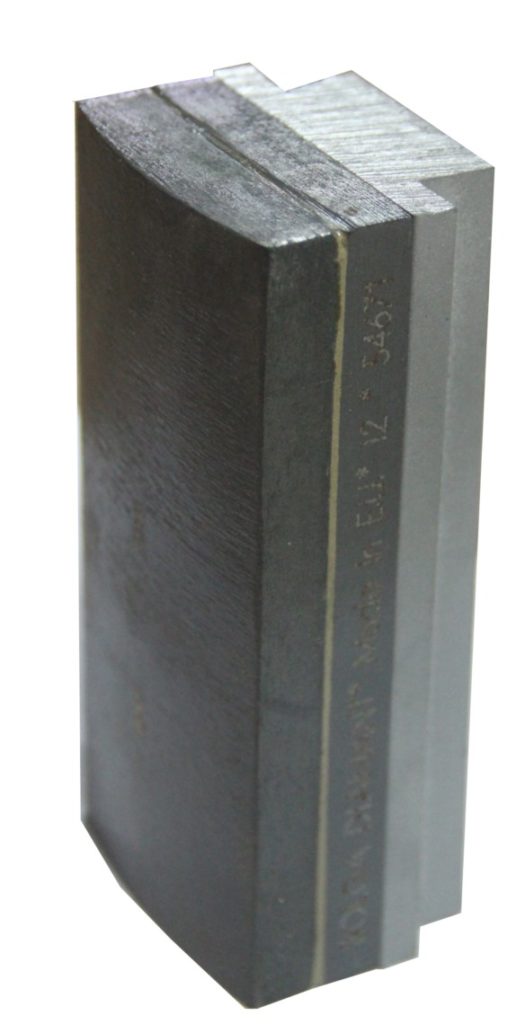

FICKERTS

FICKERTS type segments are intended for use in high-production granite polishing machines